Cables are a necessary part of any electronic setup, and with the number of electronic devices we use on a daily basis, it’s no wonder that cable clutter has become a problem.

No one likes a jumbled-up rat’s nest of cables, which is not only unsightly but can also be dangerous. On the other hand, well-labelled cables lend an air of professionalism and competence to any work environment.

As anyone who has ever dealt with a tangled mess of cables knows, labelling them is essential for keeping track of what goes where. Not only does it take the guesswork out of setting up and troubleshooting your equipment, but it also saves time and money when it comes to moving, adding, or changing a cabling network.

So if you have ever looked at a nest of tangled cables and thought to yourself, “There’s got to be a better way,” well, there is! With just a little bit of time and effort, you can label your cables and cords in a way that will make it easy to find the right one every time.

In this blog post, we will show you the importance of cable labelling, the different cable labelling solutions available as well as how to label cables correctly. Read on to find out more!

What is a cable marker?

Simply put, cable markers are symbols or labels used to identify cables, wires, bundles, and conduits. They carry a variety of important details, including conductor colour value, date installed, type of cable, voltage rating, and parent/child device combination. In addition, cable markers can also provide crucial contact information for the owner, making it easy to get in touch if there are any questions or concerns.

Cable markers are available in a large variety of designs, colours, and sizes to suit any need. Common types of cable markers include dot matrix ribbons, dot matrix labels, laser sheets, laser labels, pre-printed tape markers, and self-laminating labels. They can also be constructed from different materials depending on the application, including nylon, metalized polyester, plain polyester, cloth, vinyl, or steel.

Why do cables need to be labelled?

Some of the advantages of labelling cables include:

- Keeping track of different cables: Proper cable labelling allows for easy identification of specific cables in a fibre network or cabling system, preventing individuals from tampering with particular cables and consequently limiting the risk of downtime.

- Eliminate guesswork, thereby saving time: You will save time and energy trying to identify and fix a problem when you can easily locate it. When you need to add or remove a wire from a pool of cables, it is a much simpler process when all of them are neatly labelled than having to search through an unlabeled mass of cables. This is especially important in time-sensitive situations.

- Prevent costly mistakes: Mislabelling or failing to label cables could result in connecting the wrong devices, which could cause expensive damage.

- Organise your space: A well-labelled space is a more organized space. This is not only aesthetically pleasing but can also help you find things more easily.

- Clarity: Cable labelling is also crucial for new employees to enable them to understand the cable/fibre network long after the cables have been installed. If a network administrator quits or personnel changes occur in an organization, new technicians can easily get familiar with the cable network or the network system using the labelled cables. This consequently allows for simpler troubleshooting and maintenance procedures, which also saves time and costs of repairs and expansions.

- Compliance: Correctly labelling cables ensures audit compliance and quality assurance. In many cases, cables must be labelled according to specific standards to ensure safety and interoperability. Each industry might have its own given requirements for labelling. This can include things like the size and type of font to be used, as well as the specific information that needs to be included on the cables.

- Easy identification: Labelling infrastructure components also reduces the cost of ownership by allowing for comprehensive identification in dynamic management and administration systems.

Choosing the Right Cable Labels

When choosing the right cable label, there are a few important things to consider:

Specific Application

The type of label you ultimately choose for your cords and cables should be dictated by the specific application or use case. For example, if you plan on labelling cords that are mainly used in a home or office setting, then you’ll likely want to choose labels that are more aesthetically pleasing and easier to apply. Conversely, if you’re labelling cords that will be used in an industrial setting, then sturdier materials and more durable labels may be necessary. Other factors to consider include how frequently the labels will need to be changed or replaced (if at all).

Environment

It is most important to gauge the level of abuse or exposure to which the labels will be subjected. Will the label be exposed to high temperatures? Moisture? Chemicals? The answer to these questions will help determine the type of label material and adhesive that will be best suited for your needs.

If you’re in an industrial setting or a busy office, you’ll need wire labels that can withstand a lot of wear and tear. If you’re working in a damp or wet environment, you’ll need a label that is resistant to moisture. If you’re labelling cables that will be exposed to sunlight, you’ll need a label that is UV-resistant. In general, it is best to err on the side of caution and choose a label that can withstand a wide range of environmental conditions.

Understanding the specific environment and how it affects markers saves you the expenses and costs of regularly replacing faded cable labels.

Size Matters

When choosing a cable label, be sure to consider the size of the label and the size of the cable. Choosing the right size label will help ensure that the label can be easily seen and read, making it easier to identify and manage your cables.

If the label is too small, it may be difficult to read. If the label is too large, it may not fit on the cable. Measure the cable, as the ideal label size will depend on the specific application. For example, labels used on data cables or network cables may need to be small enough to fit on the cable jacket, while labels used on power cables or bulky data cables may need to be larger so that they can be easily seen and read.

The rule of the thumb when choosing the correct size of the marker is that the length of the label should be five times the size of the wire’s outer diameter.

Regulations

Unsure of what kind of label to choose for your cables? Regulations may be one consideration you hadn’t thought of. Various industries have specific standards that must be met when it comes to labelling.

Many industries have specific standards that must be met when it comes to labelling, so it’s important to be aware of these standards before making your purchase. Not only will this help you to stay in compliance with the law, but it will also ensure that your wire labels are up to industry standards. In addition to checking industry regulations, you should also check your local, state, and federal government laws and regulations in regards to cable labelling.

Some examples of Cable labelling standards include the ANSI TIA 606-B standard.

Type of Material

If you are working with cables, you need to make sure that you choose the right type of material for your cable label. This is because different materials have different properties, making them more or less effective for different applications. For example, some materials are more flexible than others. Other materials are more durable and resistant to abrasion, making them a good choice for outdoor applications or for labelling cables that will be subject to a lot of wear and tear.

Teflon and polyolefin labels can withstand harsh conditions, therefore, are best suited for corrosive chemicals and extreme temperatures. Polyolefin is a class of thermoplastics that encompass polyethene (PE) and polypropylene (PP). PE and PP offer excellent extreme heat and chemical and moisture resistance properties.

Vinyl cable markers are best suited for greasy and dirty environments as they can sustain oil and dirt. Vinyl is also compatible with non-flat sub-surfaces, while nylon’s immense strength and flexibility make it an excellent choice for curved cables/wires.

Label Placement

Depending on where you intend to place the label, different types of markers may be more appropriate.

When it comes to placement, we have two major types of markers–those that must be used before termination (slipped over the open end of a wire-like in the case of wire marker sleeves) and those that can be used either before or after termination (self-laminating and wrap-around, which can be easily placed on any section of the cable).

The Different Types of Cable Markers

There are different types of wire markers, ranging from adhesive wraps to sleeves (also known as shrink tubing) and flags. The choice of marker depends on whether a permanent or temporary label is required, an adhesive or non-adhesive label, and a self-laminating fixed label or repositionable marker for rotating, which allows for easy reading.

The cable markers available include:

- Wraparound Cable Markers

- Electrical Cable Markers

- Adhesive Cable Labels

- Attached Cable Markers

There are many different types of cable labels available on the market, each designed for a specific purpose. Some of the most popular options include:

Cable Flags

Cable flags are ideal for imprinting larger amounts of labelling information on small diameter wires and cables, including fibre optic cables. Cable flags can either be P-or T-shaped and are a perfect solution for identifying cables and wires, which require detailed information for identification. They wrap around the outside of the cable and are usually made of brightly coloured durable vinyl, metal, or polyester. The ends of the flag are applied together to form a “flag” that can be easily seen.

The flags hang neatly on the cables or wires, allowing for easy cable identification and management. In most cases, they are looped around the cable and then fastened between the two printable halves securely, making them a great solution for labelling cables that are already attached. For added convenience, many cable flags come with pre-printed numbering or lettered systems.

Cable flags are ideal for labelling fibre optic, coaxial, USB, network cables, lockout tagout boxes, ports, data centres, computer cords, devices and much more. Cable flags come in different colours, with the common ones being white, green, seafoam, blue, red, yellow, orange, lemon, violet, or silver, making them suitable for colour-coding. Besides, they can be constructed from different materials, including steel, nylon, vinyl, Teflon etc., to attain different resistance properties, including corrosion-resistant, abrasion-resistant, chemical-resistant, UV-resistant, weather-resistant, humidity-resistant, thermal resistant and more.

Coloured Zip Ties

Coloured zip ties are ideal for cable identification using colour, i.e. colour coding. They are ideal for identifying different cable combinations and bundling cables of the same nature, purpose or characteristics together. Besides aiding in cable identification, zip ties can also be used to lock cables firmly, preventing slipping and disorganization. Their self-locking design makes cable/wires networks tidy and organized.

Zip ties come in a wide range of colours; therefore, you can choose specific colours to differentiate cable combinations. They are mostly constructed using nylon and vinyl, making them flexible with strong load ability. Coloured zip-ties also come with other properties, including anti-acid, anti-ageing, anti-corrosion and static thermal sustainability, i.e., 30℃ to 85℃.

Coloured Tape

Coloured tapes are another cable labelling solution in circumstances where colour is used to identify specific labels. By using colour coding, the labelling and identification process is much more simplified, considering that it might be challenging to read longer texts around surfaces of a thin cable.

Depending on the material used in construction, coloured tapes are usually tear-resistant, oil-proof, waterproof, flexible and self-adhesive. As such, they can be used both indoors and outdoors.

Heat-Shrink Tubes

Heat-shrink tubes are perfect for un-terminated wires or cables requiring superior abrasion and chemical resistance. The label comes in the form of a tube that you can slip onto the open end of the cable then using a heat gun; the high temperatures shrink the tube to fit the size of the concealed cable. Heat-shrink tubes come in full design, providing a fast and permanent wire marking solution.

There are different types of heat shrink labels available in the market, with the common ones being PVC shrink labels, PET shrink labels, and OPS shrink labels. PVC shrink labels are the most cost-effective of the bunch, offer good scuff resistance, plus it’s easy to control during shrinkage. PET shrink labels, on the other hand, offer the best scuff resistance with the highest percentage of shrink. OPS shrink labels have the lowest vertical shrink for consistent finish and are more cost-effective than PET.

When choosing the ideal heat shrink label, you should consider three crucial factors: printing technology, heat shrink ratio, and the type of material.

Printable Labels

As the name suggests, printable labels come blank, allowing the user to customize the information that is printed on the label. This can be accomplished using thermal label printers. Printable labels offer a high degree of customization, as they are available in a variety of colours and sizes, and you also get to choose the colour of the printed characters if the printer supports that. In addition, most printable labels have adhesive backs, making them easy to attach to various surfaces. You can also use other methods to attach the labels, such as cable ties.

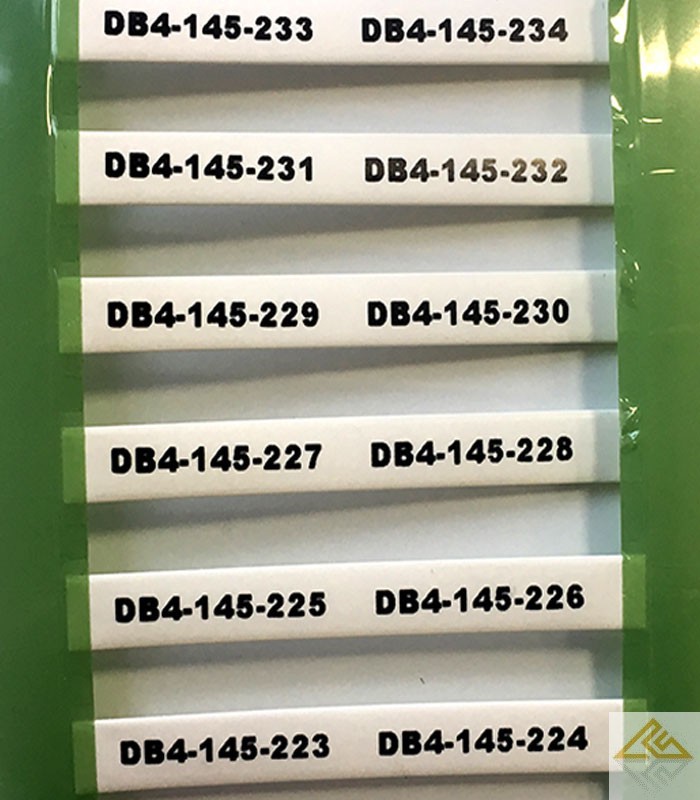

Wrap-Around Cable Labels

As their name implies, these labels essentially wrap around the entire circumference of a cable or wire, making it easy to identify each one at a glance. They are typically made from PVC, vinyl, or polyester and have an adhesive backing that allows them to be firmly attached to the cable.

These markers are ideal for marking of terminated or unterminated wires and cables that may be either curved or uncarved. Wrap-around cable labels often incorporate strong, long-lasting acrylic adhesives that are resistant to high/low temperatures.

They are available in both pre-printed and printed forms and offer an easy way to identify telecommunication and datacom.

There are many benefits to using wrap-around cable labels, as they allow for quick and easy identification of cables and wires without the need for any special tools or equipment. In addition, these labels can also be easily read from both ends of the cable. Also, depending on the material, wrap-around cable labels are very durable and resist abrasion, making them an excellent choice for use in harsh environments.

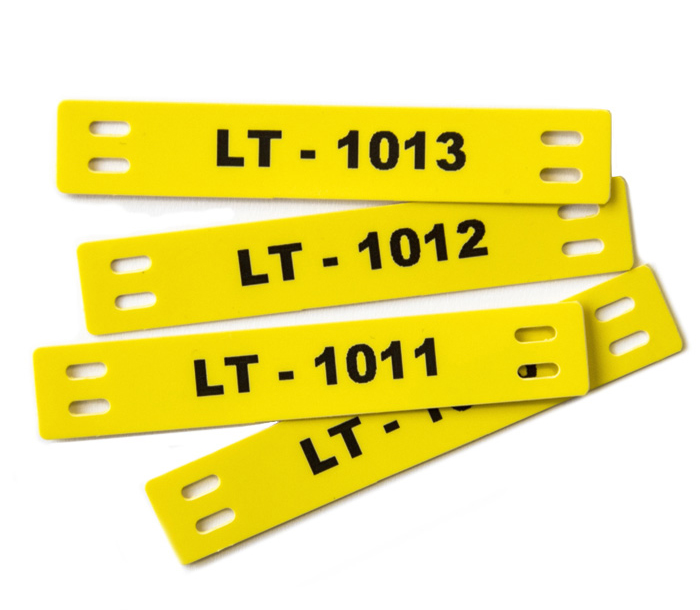

Cable Identification Tags

Cable identification tags are usually attached with cable ties and provide plenty of space for identification information. These tags allow you to create clear, unambiguous cable identification imprints for both indoor and outdoor environments. The tags are then attached to cable, wire or bundles using a lacing cord or cable ties.

Cable ID tags are constructed from different materials, including Zero Halogen material, traffolyte, and stainless steel, conferring different environmental properties.

Self-Laminating Labels

Self-laminating labels don’t require any form of adhesive to bond to the cable. Instead, they incorporate adhesives allowing for fast and easy labelling. The label is created by sandwiching a strip of printable material between two pieces of laminate that act as a protection barrier against external elements.

Material Used in Cable Labelling and Possible Application Area

Labels are made using different materials, each with specific qualities. Common materials used in cable labelling and possible application area include:

- Polyolefin– Polyolefins are synthetic polymers consisting of olefinic monomers. Polyethene and polypropylene are the most common forms of polyolefins with widespread applications in different industries. Polyolefin makers are legible in wet environments, non-toxic, durable, heat-resistant and can withstand most kinds of chemical erosion. As such, they are best for use in harsh industrial environments.

- Vinyl– Vinyl is a broad class of polymers derived from vinyl monomers. Vinyl cable markers are flexible and provide remarkable oil and dirt resistance. They are ideal for non-flat sub-surfaces.

- Nylon– Nylon is a popular synthetic material with a wide range of applications ranging from apparel, consumer goods, industries and more. Nylon cable labels are perfect for curved surfaces as they are both flexible and incredibly strong. What’s more, nylon markers provide excellent resistance against chemicals and extreme temperature ranges.

- Steel– Steel is a strong and durable metal that is often used in cable labelling. Steel labels can withstand harsh industrial environments, including corrosion, acids, heat, cold, chemicals, etc. They are also ideal for outdoor applications and allow for easy attachment with cable ties.

- Paper-Paper labels are mostly used for indoor cable labelling, and although paper labels are not as durable as some of the other options, they can still last a long time if they are used correctly. Paper labels are best for short-term use and should not be used in places where they can get wet or damaged easily, i.e. indoors. However, one of the advantages of paper labels is that they are less expensive than other options.

- If you need a short-term or temporary solution, paper labels may be the best choice for you. However, keep in mind that they will not last as long as some of the other options.

Proper Cable Labelling Practices

One of the most important yet often overlooked aspects of cable and wire management is proper labelling and identification. Without properly labelled cables, it can be difficult to achieve the intended purpose of labelling the cabling network. Not to mention, improper cable labelling can lead to significant confusion. Some proper cable labelling practices include:

- Choose high-quality labels that are not prone to tearing and are also resistant to water and smudge.

- Making it legible: The label should be easily readable so that anyone can understand it at a glance. This means using clear and concise text and avoiding abbreviations as much as possible.

- Labels should be placed in a clear and visible location.

- Label both ends of each cable – It’s important to label both ends of each cable so that you can easily identify which end goes where.

- Avoid writing information on labels by hand as the words can easily wear off. Instead, print the labels preferably using laser printers.

- While labelling cables, be sure to use a standardized labelling system. One common uniform labelling system is the TIA-606 voluntary standard which establishes guidelines for labelling cables in different facilities. Uniform labelling standards often adopt a certain format of cable labelling in such a way that it illustrates the required information in a standardized and organized form.

- Use standard symbols and abbreviations when need be to ensure that everyone understands the meaning of the label.

- Periodic checks should be carried out on the cabling system to ensure that the labels are in excellent shape and clearly visible.

- Cable and wires labelling systems should be updated periodically to reflect future upgrades.

- IT personnel and facility managers should maintain a permanent record of the original cable label installation as well as the subsequent changes. This can be useful for reference and for troubleshooting in case of problems.

- Colours may be used on cable labels and tags for aesthetic purposes or to clearly differentiate different types of cables and wires

- Including pertinent information on each label, such as cable type, length, destination, etc.

- Applying it correctly: Apply the label to the cable in a way that won’t damage the cable or impede its function.

Following these practices will ensure that your cable labelling is effective and up to par. Not only will it make things easier for you, but for anyone who needs to work with the cables in the future, properly.

Label Your Cables Today!

Properly marking and identifying cables and wires in a cabling system is essential to attain overall project efficiency and avert time and cost wastages when adding or revamping cable networks. Regardless of how small or large, simple or intricate a cabling job may be, proper labelling of every cable or wire is essential for both efficiency and workplace safety and ensures compliance with set regulations. Failing to undertake proper labelling could greatly lead to loss of productivity and risk of injuries.

Proper wire/cable labelling cannot be overemphasized. At Lucas Products & Services, we offer industrial labelling solutions innovative cable labelling technology, enhancing efficiency in the cabling system. We offer cable labels in multiple colours, fonts and materials to meet your specific needs. Get in touch today to learn more about our comprehensive marking products.